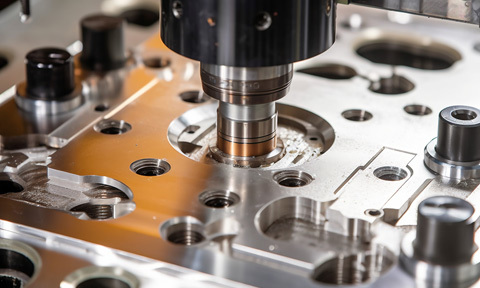

中機鍛壓江蘇股份有限公司是中國機械科學研究總院旗下三級央企,是北京機電研究所控股子公司,專精特新小巨人企業,服務型制造企業,江蘇省高新技術企業,海安市“創新型領軍企業”、“工業百強企業”

關于中機

關于我們

About Us

中機鍛壓江蘇股份有限公司是中國機械科學研究總院旗下三級央企,是北京機電研究所控股子公司,國家級專精特新小巨人企業,國家級服務型制造企業,江蘇省高新技術企業,海安市“創新型領軍企業”、“工業百強企業”,位于中國最具活力的長三角北翼、中國東部沿海與蘇北沿江高鐵及高速公路交匯處——國家級海安經濟技術開發區......

中機文化

ENTERPRISE CULTURE

發展目標

創中國鍛壓品牌

做世界知名企業

核心價值觀

為客戶創造價值 為員工創造機會

為股東創造效益 為社會承擔責任

質量方針

顧客為本 誠信服務

持續創新 精益求精

發展戰略

控制關鍵 掌握核心

立足高端 面向國際

經營理念

崇匠務實 勤勉敬業

追求精益 敢為人先

服務理念

專業經營 誠信服務

顧客至上

資質榮譽

創中國鍛壓品牌 · 做世界知名企業

微信公眾號

抖音號